Manufacturing

Fiberglass is a unique material for solving your challenges!

One of the main specializations of our activity is the serial and custom production according to the customer’s technical requirements.

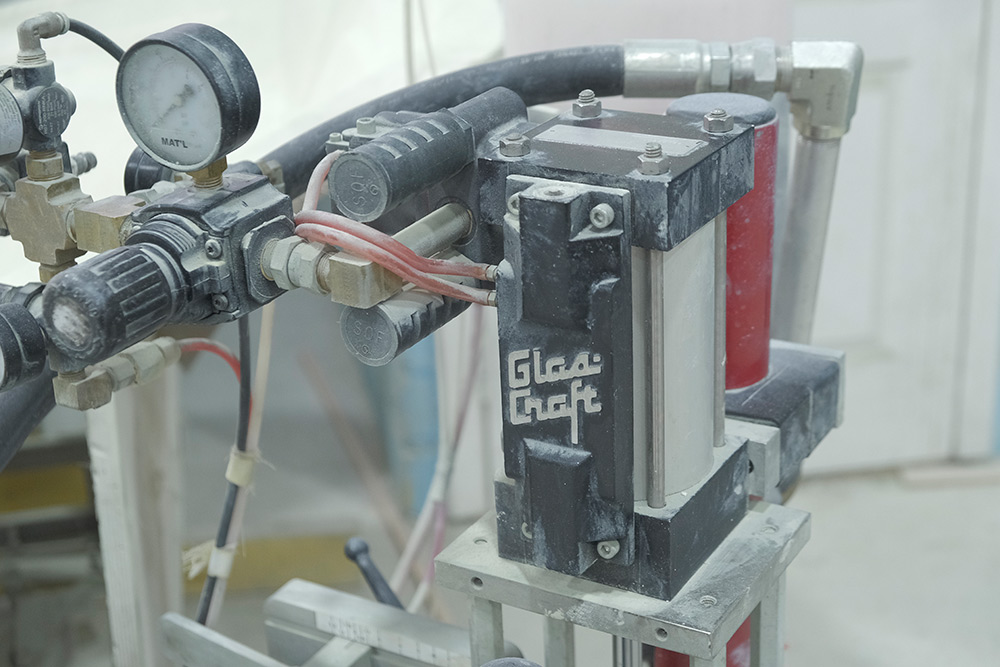

EQUIPMENT

The company “Astacomposite” operates equipment for the production of composite products, as well as for applying gel

coat and paints from leading global manufacturers.

If necessary, fiberglass products can be painted.

PAINTING OF PRODUCTS

The surface is prepared for the appropriate type of enamel, and a primer recommended for this type of enamel is applied. A special gel coat for coloring may also be used.

The color of fiberglass products is determined by the color (RAL) of the gel coat applied. At the beginning of the production process of fiberglass products, the gel coat is applied to the mold, followed by layers of fiberglass fabric impregnated with resin.

MOLDING

CUTTING

For the production of large fiberglass products, there is a need to design detachable structures. The components of the fiberglass products must fit together perfectly, and the entire structure must be strong when assembled.

MANUFACTURING OF LARGE MOLDS

The master model of future fiberglass products must be precisely constructed in volume. In this case, the production of fiberglass products is impossible without the use of a CNC (Computer Numerical Control) machine and experienced personnel.

FINISHING

Work is carried out on cylindrical and surface grinding equipment.

POLISHING